Knitting can be divided into two principal categories: weft knitting and warp knitting. Today, we, Aungwinter, a reliable Chinese custom manufacturer of winter hats, beanies, and accessories, will introduce about weft knitting. What’s weft knitting? The main fabrics for weft knitting, the main process, and the difference between weft knitting and warp knitting.

What’s Weft Knitting?

Weft knitting is a craft of knitting that bends yarns horizontally into a circle and weaves them into a textile. The core feature is to bend yarns horizontally, knitting them into a circle in an orderly manner, and then stringing them together to weave them into a fabric. Here are common fabrics that are often used for weft knitting.

Natural fabrics:

Cotton is soft, skin-friendly, and moisture-wicking, which makes it suitable for intimate outfits. Wool is warm and stretchy, which is ideal for winter clothes. Silk is lightweight with great luster, which is suitable for high-end garments. Linen is breathable and stiff, which is suitable for summer clothing.

Chemical Fabrics:

Polyester is wear-resistant and can easily keep its great shape, which is suitable for sports wear. Nylon is great at elasticity and strength, which makes it suitable for tights and socks. Acrylic fabric has similar properties to wool – sunlight resistance, wear resistance, which is great for knitwear and sweaters. Spandex is excellent at elasticity and can be blended with other fabrics to improve the elasticity, and is often used for tight outfits and sportswear.

Blended Fabrics:

Blended fabrics combine the pros of blended fabrics. For example, blended wool and polyester fabrics combine the warmth of wool and the durability of polyester. Blended cotton and spandex fabrics blend the comfort of cotton and the elasticity of spandex. Therefore, blended fabrics are widely applied in many fields.

The Main Process of Weft Knitting

The main process of the weft knitting can be divided into fabric preparation, spinning, treatment before dyeing, dye & patterns, and finishing. Each process is closely related to the others, and all of them determine the fabric quality.

1. Fabric Preparation:

This step is about the pre-processed of fibrous material that is selected, like cotton, wool, or chemical fibers. This step aims to remove impurity, dust, and short fibers to ensure to get clean raw materials. Then comb fibers into continuous cotton sliver in a vertical order, which can ensure the evenness of raw materials and reduce the broken problem when woven.

2. Spinning:

The carded fibers are spun into yarns that meet the requirements through processes such as drawing, roving, and spinning. Drawing combines multiple cotton slivers for drawing to improve the fabric balance. Roving means twisting coarse yarn into even-fine and proper-strong yarns. Yarns for the weft knitting need to have some elasticity and strength. Based on the fabric requirements, the twist can be adjusted. For example, low twist is suitable for soft fabrics, and high twist is suitable for stiff fabrics.

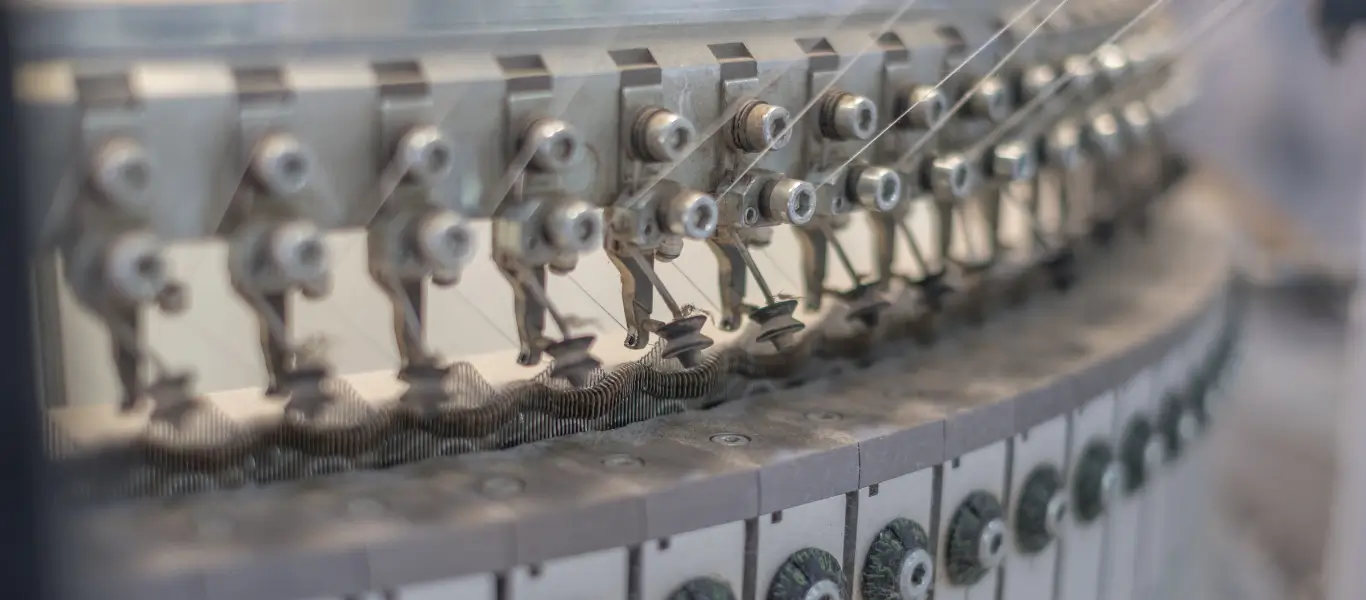

3. Woven/Knitting:

Yarns can be woven into greige fabric through weft knitting machines. The knitting needles form loops in sequence in the transverse direction, and the yarn is connected from one side, forming loops around the knitting needles and interlacing with each other to form a continuous fabric. Different weft knitting machines can weave different greige fabrics like plain woven fabrics or ribbed fabrics.

4. Treatment Before Dyeing:

Steps before dyeing and finishing: Greige fabrics undergo desizing, scouring, bleaching, and other processes to make the fabric clean and soft to the touch, creating a nice base for subsequent dyeing uniformity. Weft-knitted fabrics containing wool also need to be treated to prevent shrinkage and deformation after washing.

5. Dye & Patterns:

Dye and patterns: According to the design, pre-dyeing or pre-patterning treatment will be processed. Dyeing is adopted, including dip dyeing and pad dyeing, to make colors even on greige fabrics. Patterns will be through screen printing and digital printing. Because weft knitting is bouncy, when dyeing, please control the temperature and time to prevent shrinking. It’s important to make the completion of the whole pattern when greige fabrics are stretchy.

6. Finishing:

This step is a key process to boost the function of fabrics, including stretching, pre-shrinking, softening, shaping, etc. Functional fabrics will add anti-bacterial doses or anti-UV techs, giving extra functions.

The Difference between Weft Knitting and Warp Knitting

Weft knitting and warp knitting are the common knitting crafts with obvious differences in many aspects. Here are the key parts to tell weft knitting and warp knitting.

1. Spinning Directions:

The direction of spinning yarns is a great way to tell whether it’s weft knitting or warp knitting. Weft knitting, yarns are fed horizontally like beads, and each yarn is woven horizontally to be woven into textiles. Warp knitting involves many yarns in a vertical order to weave at the same time, and each yarn forms a vertical circular chain.

2. Elastic and Structure:

Elastic and structure can also tell whether it’s weft knitting or warp knitting. Usually, the connection between weft knitting is relatively loose, so the stretch of weft knitting is great and can recover soon after stretching. However, if one knitting circular yarn breaks, the surrounding yarns will be lost. The structure of warp knitting is tight, and there is little stretch at the horizontal sides, with strong stability. Even if one circular yarn is broken, it’s not easy to lose the surrounding parts.

3. Device/Machine:

In general, machines or devices for weft knitting are circular and flat knitting machines. Circular machines can weave tubular or spiral cloth for T-shirts. Flat machines are suitable for weaving cloth for sweaters, and they are flexible to operate and easy to change textures. Warp knitting machines for warp knitting are complex and can weave wide cloth with complex patterns.

4. Usages/Applications:

Fabrics made with weft knitting are soft and stretchable and are therefore used to make intimate apparel, undergarments, T-shirts, sports garments, and sweaters. Warp knitted fabric is more rigid and resilient to deformation, and is used in the manufacture of outer garments, draperies, upholstery of sofas, and some industrial filter fabrics constructed of curtain fabrics.

5. Production Features:

Weft knitting is suitable for small bulk production and various types of products because it’s easy to change colors and patterns. Warp knitting is suitable for large production because it needs to adjust so many parts when changing patterns or styles, with pretty high costs.

Conclusion

Comprehensively, based on its unique features, rich fabrics, and exquisite weft knitting production, knitting has occupied an important place in the textile industry. The advantages of weft knitting make it widely applicable among intimate outfits, home decorations, etc. With future tech innovations, weft knitting will have even more potential.