Table of Contents

Coated fabric

It is a fabric treated with a special process. It can form a uniform layer of covering rubber on the surface of the fabric, thus achieving waterproof, windproof, breathable and other functions.

Coating, also known as glue coating

i.e. acrylic coating

It is the most common coating currently

As a clothing person,

15 kinds of coatings that must be known,

How many kinds do you know?

PA coating

PA coating, polyacrylate fabric coating adhesive (Polyacrylate abbreviated as PA), also known as AC adhesive coating, is currently the most common and common coating. After coating, it can increase the hand feel, wind resistance, and have a sense of drooping. It is commonly used for anti-fur, hand feel, color fixing and sand fixing. There are also acrylic and pony glue, which are solvent-based acrylic coatings suitable for water pressure resistant coatings. The price is slightly higher than AC.

Advantages:

a. Good light and weather fastness, not prone to yellowing;

b. Good transparency and compatibility, which is beneficial for the production of colored coating products;

c. Good washability;

d. Strong adhesion;

e. Low cost.

Disadvantages:

a. Poor elasticity, easy to wrinkle;

b. Poor surface finish;

c. It is difficult to adjust the hand feel to a moderate level.

PU coating

Polyurethane coating (PU for short), also known by its full name polyurethane, gives fabric an elastic yet film-like surface after coating.

PU coating is a polymeric compound consisting of molecules with NHCOO units in its molecular structure, formed through the reaction between isocyanate groups and hydroxyl groups; its chemical formula being N=C=O+HO—NH-COO. First synthesized in Germany in the 1970s. Around 1950, polyurethanes first made an appearance in Europe as textile finishing agents; mostly as solvent-based dry coating products. By the 1960s, however, waterborne PU coatings began appearing due to increased environmental awareness and government regulations for environmental regulations. Following the 1970s, water-based polyurethane coatings saw rapid development and widespread usage in fabrics coated with them. Since the 1980s, however, breakthroughs in research and application technology of PU were achieved compared with foreign countries, although domestic research into polyurethane textile finishing agents is relatively late; instead polyurethane coating agents are the main focus for development today.

Advantages:

a.Soft and elastic coating provides maximum protection;

b. Excellent coating strength for very thin coatings;

c. The coating is porous and permeable to moisture and air;

d. Resilient to wear, moisture and dry cleaning.

Disadvantages:

a. Higher Cost;

b. Poor Weather Resistance;

c. PU coatings require hydrolysis using water, heat and alkali for proper synthesis.

Their composition includes polyester polyurethane; polyether polyurethane; aromatic isocyanate polyurethane and aliphatic isocyanate polyurethanes. Based on the medium used they can also be divided into solvent-based and water-based categories.

Anti velvet coating

It refers to the anti-down coating, which can prevent down from escaping after coating, and is suitable for making down jacket fabrics. However, now PA coatings with water pressure requirements are also called anti-down coatings.

PA white glue coating

It refers to the anti-down coating, which can prevent down from escaping after coating, and is suitable for making down jacket fabrics. However, now PA coatings with water pressure requirements are also called anti-down coatings.

PU white glue coating

That is, a layer of white polyurethane resin is applied to the surface of the fabric, which functions essentially the same as PA white glue, but the PU white glue has a fuller feel, the fabric is more elastic, and the fastness is better.

PA silver gel coating

That is, a layer of silver-white glue is applied on the surface of the fabric to make the fabric have the function of shading and simulating radiation. It is generally used for curtains, tents, and clothing.

PU silver coating

The basic function is the same as PA silver coating. However, PU coated silver fabric has better elasticity and better fastness. For fabrics such as tents that require high water pressure, PU coated silver is better than PA coated silver.

Pearlescent coating

By coating the surface of the fabric with pearlescent coating, the surface of the fabric has a pearly luster, silver and colorful. It is very beautiful to make into clothes. There are also PA pearlescent and PU pearlescent, and PU pearlescent is smoother and brighter than PA pearlescent, with better film feel, and is better known as “pearl film”.

Oil gloss coating

The surface is smooth and shiny after coating, and it is generally suitable for daily use in the home, such as tablecloths.

Silicon high-elastic coating

Also known as a paper-like coating. It is suitable for thin cotton fabrics as a shirt lining, with a full feel, crispness, and elasticity, as well as strong resiliency and wrinkle resistance. For thicker fabrics, it has good elasticity and fastness.

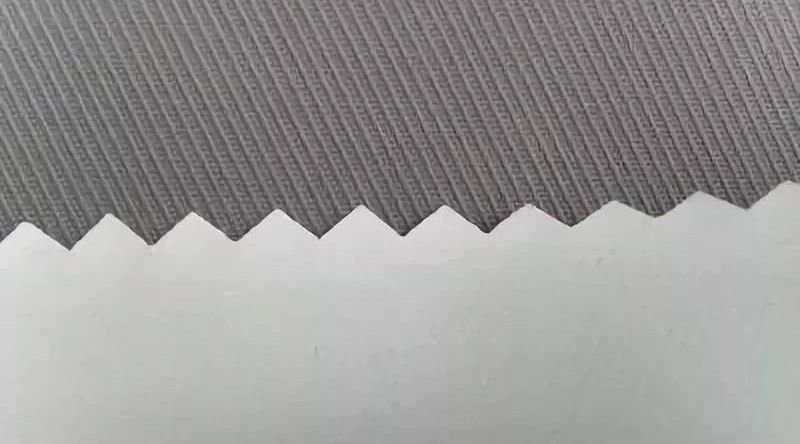

Film coating

By calendering and coating the surface of the fabric, a film is formed on the surface of the fabric, completely changing the style of the fabric. Generally, the film surface is made into the front of the garment, with a leather-like style. There are two types: matte and glossy, and various colors can be added to the coating to make a colorful film, which is very beautiful.

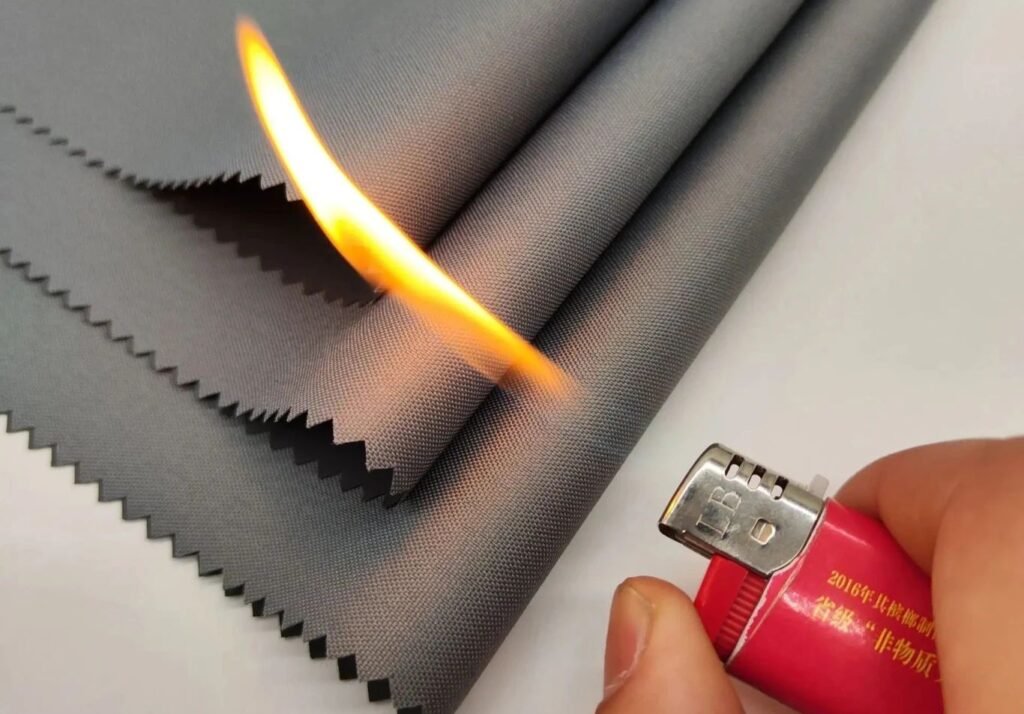

flame retardant coating

By dipping or coating the fabric, it can achieve flame retardant effect. It can also be painted with color or silver on the surface. It is commonly used for curtains, tents, and clothing.

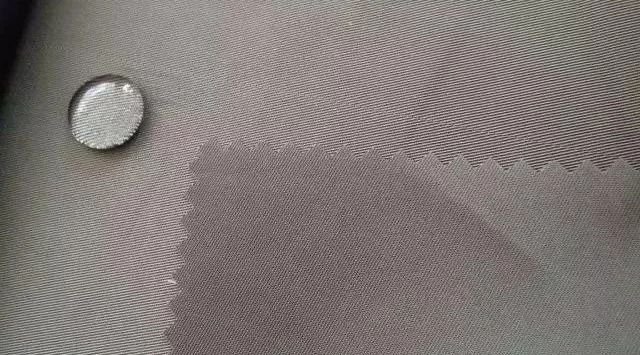

Special service dragon three-proof

By treating fabrics with DuPont Teflon, the fabrics have waterproof, oil-proof and stain-proof functions.

UV resistant coating

By treating fabric with anti-ultraviolet treatments, such as those found on sunscreen umbrellas and clothing available on the market, its performance as an anti-ultraviolet barrier increases dramatically. Anti-UV properties include the ability to block ultraviolet penetration. Light colors tend to be difficult for this function while dark hues usually make this easier; coatings on fabrics such as sunscreen umbrellas provide this standard more readily than lighter colors do.

Special cotton coating

Such as: cotton scrape coating, paper-like coating, washed-out coating, hidden pattern coating, oil-like wax-like coating, colorful leather coating, etc.